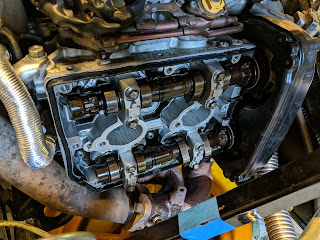

- Engine

- I took off the passenger side valve cover to measure the valve lash on the rebuilt head I purchased from eBay. Sure enough, 6 out of 8 valves had a clearance of under .002″ (tolerance is .008″ +/- .0008 for intake and .010 +/- .0008″ for exhaust) meaning I could not measure them so they may have been “.001, 0”, or negative which would explain why I don’t have compression since the valves are being held open just slightly. I don’t know why exactly this is the case but my best bet is the machinist took some material out of the valve seats, moving them up towards the cam, but did not adjust the shims or valve length to compensate.

- Good news: This head has the earlier shimmed valve buckets so I can replace them without pulling the cams, and therefore the timing belt system. Bad news: this won’t happen until after the Summer so I won’t know for sure that everything is good for a few months.

- Summer Break

- With my school semester over, I am back up in Michigan continuing my co-op with General Motors. Unfortunately the 818 could not come along so progress on the kit will be stalled until mid August. But I’ll have some thinking time to decide how to tackle my more time consuming efforts of resolving the brake master cylinder setup, coolant pipe leak fixes, and such.