- Engine:

- Still working through the little issues. Finding new leaks every time I start it so far…Fixed a small coolant leak from a hose clamp this time.

- Throttle cable installed

- I’ll have to change my throttle pedal mounting solution because right now there is too much angle on the cable firewall connection and it’s causing some resistance.

- Clutch:

- I plumbed the clutch line and bled the system. It is surprisingly difficult to bend the lines in a way that is clean, install-able, and correct! I’d give myself a 7/10 for the clutch line but hopefully the practice will help be do better with the brake lines (which I have 4 of because of ABS).

- Clutch works now though! I think there’s still a little air in the system but it was the best I could do with only a vacuum pump. I’ve always found the 2-person pedal pumping method to work best.

- Seats:

- I created a custom seat mount design in Solidworks CAD. I made the bracket so that it would work for both sides without requiring unique designs. I cut the pieces with a waterjet I have access to at Georgia Tech.

- I should have them painted and installed in a couple weeks.

- Small issues:

- My sparco seat sliders I got for cheap are not compatible with the Corbeau seats

- The passenger-side fit is VERY tight (see photo). Installing the seat on that side is going to be very fun. I didn’t realize the space in the cockpit was so small.

- The rear underside of my seats hits the bracket about 4 in back from the bolt holes and prevents the seat from bolting down all the way. I will have to add a 1/2 in spacer in the back to solve this.

- Shifter:

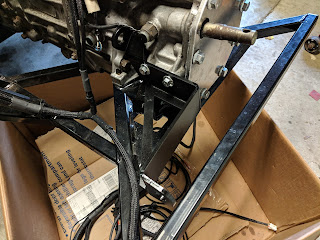

- After painting the linkage parts, I began to assemble and install the k-tuned aluminum shifter. The shifter looks awesome and the k-tuned parts are very well made! The FFR parts left a little to be desired.

- Issues with the FFR parts:

- The aluminum shifter mounting plate had incorrectly cut bolt holes so I could not bolt the shifter to it.

- Tons of rough edges that will require filing.

- The mount will need a polish so it looks as good a the k-tuned parts.

- The piece that goes onto the shift fork of the transmission was bent slightly incorrectly and made fitment a pain.

- Install isn’t quite done but should be wrapped up next time I work on the car.

- Part arrivals:

- Vintage Air A/C Parts!

- My exhaust system

Assembled Shifter

Vintage Air Parts 🙂

The misaligned holes of the FFR mount

Clutch line rear connection

Clutch line front plumbing

The seat still kinda doesn’t fit even pushed up this far 😬

Cable bracket for the shifter

Shifter transmission connection

Seat fitment on the passenger side

Seat bracket pieces before bending

Freshly cut brackets

Seat bracket orientation in the car